Three Auxiliary Technologies For PET Air Compressors That Can Reduce Costs

A high pressure compressor is a significant investment. However, many operators are taking the time to purchase an efficient and cost-effective compressed air system, but may be overlooking the opportunity with auxiliary equipment. Correctly specified accessories can actually reduce your bottom line, control and downstream air and gas quality while reducing revenue.

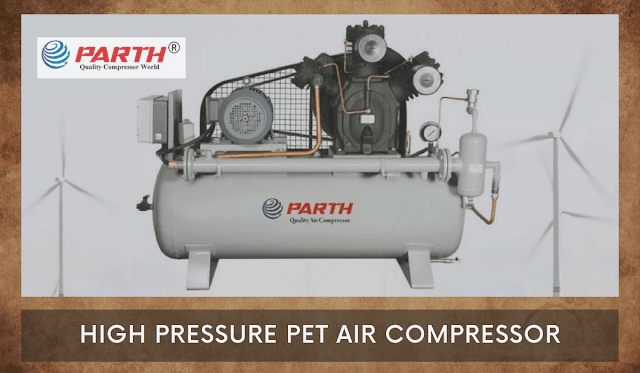

Let's take a look at some of the most effective assistive technologies that can make a real difference in the day-to-day operation of your compressor.

Air recovery: First of all, there is an opportunity to use it in an air recovery system. It is designed to accommodate the returned pressure that can be 'recycled' and reused again through the compressor.

A typical PET Air Compressor includes three stages of compression, each of these double-acting in a Bellis & Morcom machine; Depending on the customer's process, the load is evenly distributed to compress the air up to 4 bar for first stage, up to 14 bar for the second up and up to 45 bar for stage 3. However, on a standard machine the remaining compressed air is simply vented to the atmosphere when this process is complete. However, the latest technology has saved this compressed air for future use.

For example, 6 bar of compressed air can be recycled and stored. This effectively negates the first stage of compression (typically up to 4 bar) and allows compressed air to immediately pass through to the second stage. By default, the first stage of the compressor can be turned off. As you can imagine, this air return system improves the operating efficiency of the machine while reducing the cost of the operator.

With a "W" design from Belliss & Morcom, air recovery systems can be operated with additional control, efficiency and reliability - as the cylinder in the first stage can operate at 0, 50 or 100 percent load without affecting the compression ratio on the second stages. This means no change in output, operating temperature or rod load.

In fact, it can save more than 15% of the power required by high pressure air compressor machines when the air recovery system is running

Heat recovery systems are especially advantageous for locations where there is a need for hot water, room or hot water heating, and especially for those that operate for long periods of time. PET units, for example, use coolant to cool the compressor during the compressed air process. When heated through the compressor, the water is transferred to the compressor's cooling tower.

Comments

Post a Comment